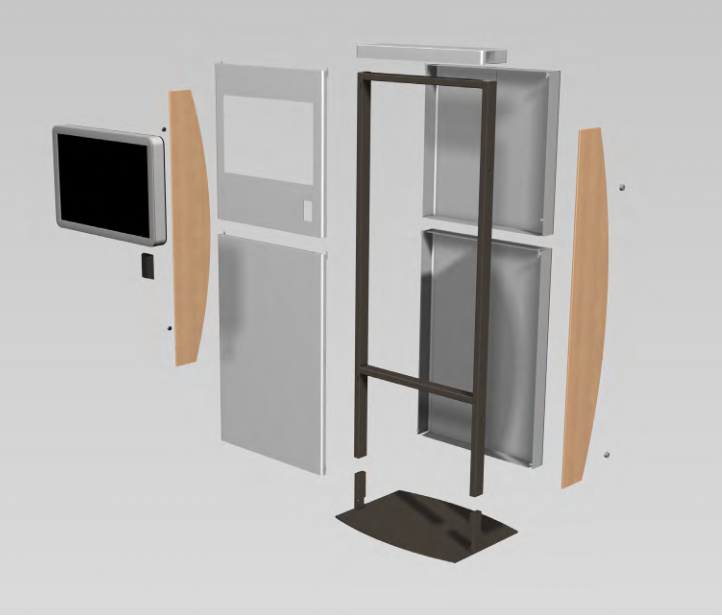

Once the customer provides approval of all the engineering details, we can move forward with in-house kiosk prototype

fabrication. The importance of being able to carry out every process under one roof cannot be overstated, as it means we have complete control to keep a project within our clients’ budgets and timelines. In fact, we even have customers come by and watch the metal being bent and welded together at times!

The electronic components that were approved in the engineering phase are purchased and brought to our facilities, then assembled into the kiosk enclosure as they come off the production line.

During the prototyping stage, we sometimes have pieces that don’t fit perfectly, illustrating the REDYREF advantage yet again. Because we fabricate in-house, we are able to make most engineering “tweaks” immediately and re-fabricate parts quickly, resulting in full runs of end products that meet the client’s requirements and expectations, allowing them to go to market quickly.