To withstand the rigors of outdoor conditions, digital outdoor kiosks must be designed, engineered, and tested to ensure they can endure almost any weather condition while delivering optimal performance. But what makes these kiosks able to withstand so many different climates and conditions?

Understanding the Importance of Weatherproofing Outdoor Kiosks

Weatherproofing is a critical aspect of outdoor digital kiosk manufacturing. This process involves fortifying the kiosk against harsh weather conditions, temperature extremes, and exposure to the elements. Effective weatherproofing -- including waterproofing -- not only protects the internal components but also extends the lifespan of the kiosk, ensuring reliable operation for years to come.

Outdoor Digital Kiosk Weatherproofing Standards

Ingress Protection (IP) Ratings

IP ratings are standardized measures that indicate a kiosk's resistance to dust and moisture ingress. The rating consists of two numbers, with the first representing protection against solid particles (e.g., dust) and the second indicating resistance to liquids (e.g., water).

For digital outdoor kiosks, a high IP rating is essential. Common IP ratings for outdoor kiosks include IP65, IP66, and even IP67, which offer varying degrees of protection against dust and water.

NEMA Ratings

The National Electrical Manufacturers Association (NEMA) also provides ratings that classify the level of protection a kiosk offers against environmental factors. NEMA ratings encompass a broader range of environmental challenges beyond dust and water, including corrosive agents and ice.

NEMA 4X, NEMA 6P, and NEMA 12 are commonly applicable ratings for outdoor kiosks, depending on the specific environmental demands.

Environmental Testing Standards

Various organizations and standards bodies have established specific testing procedures to evaluate outdoor kiosk resilience. For example, MIL-STD-810G is a military standard that outlines methods for testing equipment in harsh environmental conditions, including extreme temperatures, humidity, and vibration.

Testing Procedures for Ensuring Outdoor Kiosk Resilience

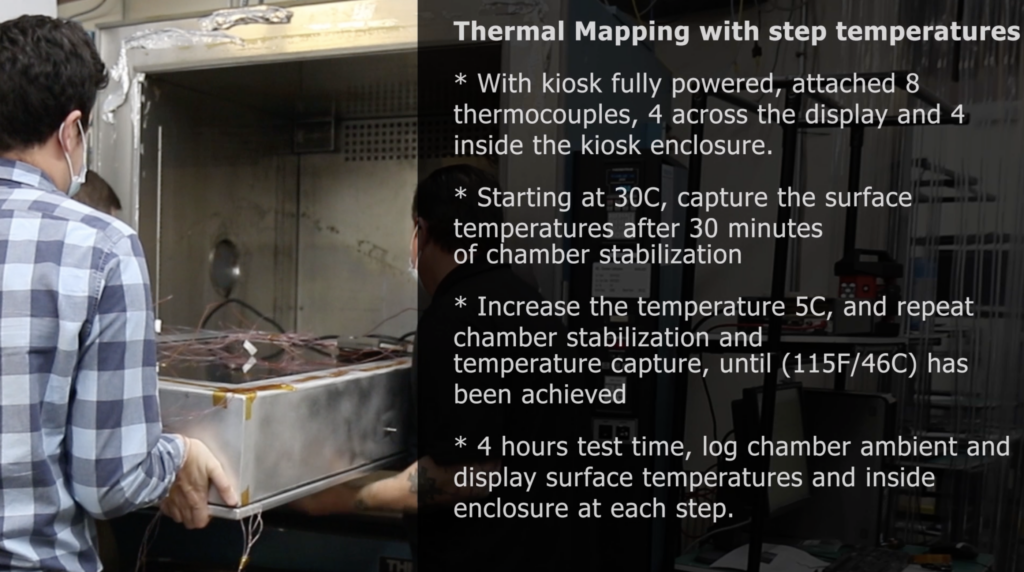

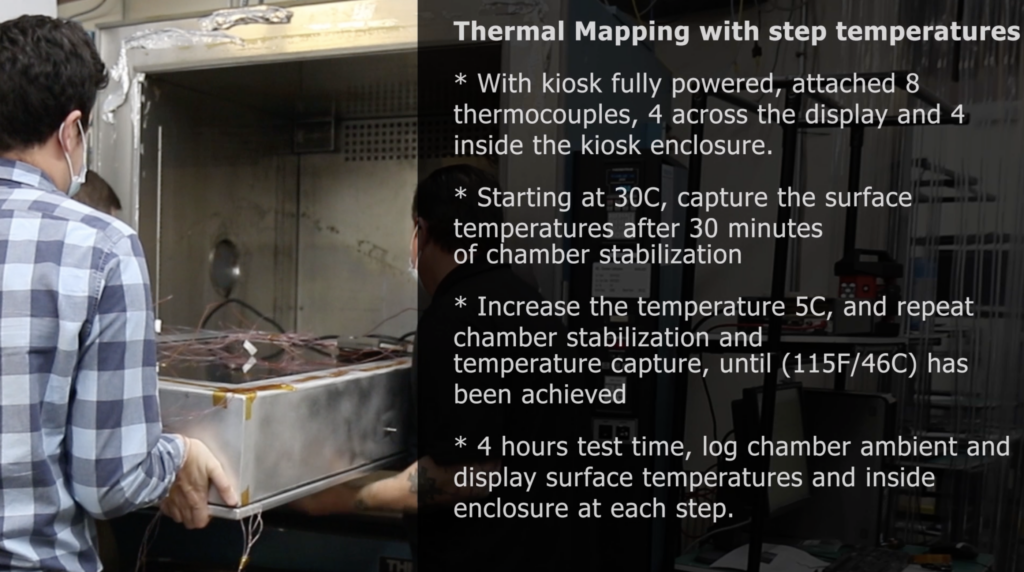

Temperature Testing

Digital outdoor kiosks must withstand extreme temperature fluctuations. Testing involves subjecting the kiosk to both high and low temperatures to ensure that internal components remain operational.

Humidity and Moisture Testing

To assess waterproofing, kiosks undergo humidity and moisture tests, which expose the kiosk to high humidity levels and water spray to simulate rain and other forms of moisture exposure.

Vibration and Shock Testing

Outdoor kiosks are often subjected to vibration and shock tests to replicate the impact of transportation or installation. This ensures that internal components remain securely fastened and functional.

Salt Spray Testing

In coastal areas, kiosks are exposed to saltwater and airborne salt particles. Salt spray testing assesses the kiosk's resistance to corrosion from saltwater exposure.

UV and Sunlight Testing

Sunlight can degrade displays and enclosure materials over time. UV and sunlight testing evaluates a kiosk's ability to withstand prolonged exposure to sunlight without fading or damage.

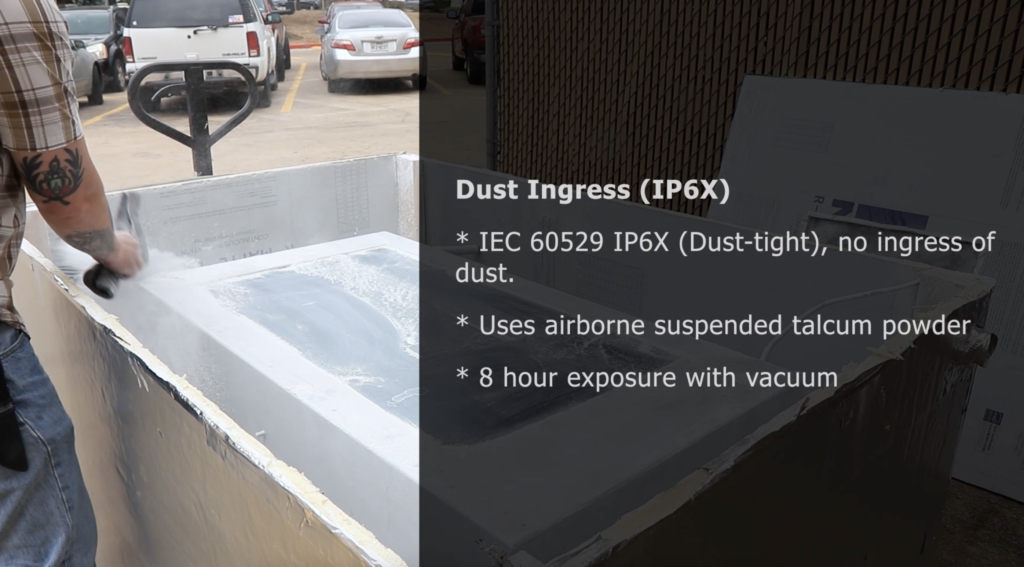

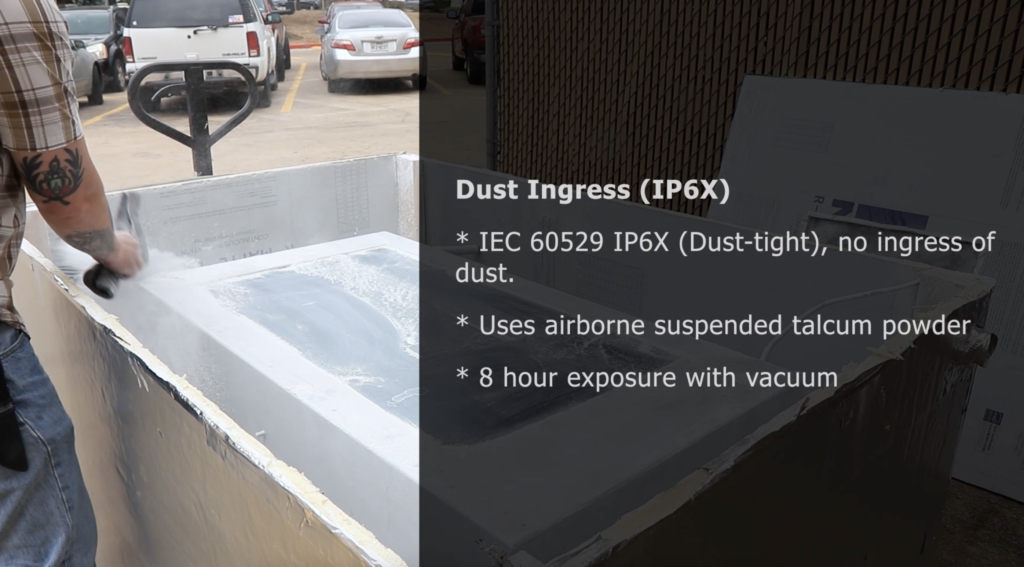

Dust and Particle Ingress Testing

To assess dust and particle resistance, kiosks are subjected to tests involving fine dust and particulate matter to ensure that internal components remain protected.

Manufacturing outdoor kiosks that are able to withstand a wide range of weather conditions and climates requires a deep understanding of weatherproofing standards, as well as the rigorous testing procedures that make successfully building these kiosks possible. As technology continues to advance, outdoor kiosk manufacturers like REDYREF will continue to innovate, ensuring that these installations remain robust, reliable, and resilient, regardless of the challenges posed by the elements.

Manufacturing outdoor kiosks that are able to withstand a wide range of weather conditions and climates requires a deep understanding of weatherproofing standards, as well as the rigorous testing procedures that make successfully building these kiosks possible. As technology continues to advance, outdoor kiosk manufacturers like REDYREF will continue to innovate, ensuring that these installations remain robust, reliable, and resilient, regardless of the challenges posed by the elements.